Our company is a professional manufacturer integrating design, production and manufacturing. The O-30 corrugated sheet forming machine produced by the company has a wide range of applications. The products produced by the machine have the characteristics of light weight, good strength, load-bearing and stable performance. They are widely used in various industrial, agricultural, commercial and civil buildings. Such as rural roof renewal projects, port warehousing, simple residential projects, earthquake-resistant or wind-resistant temporary residences, factory reconstruction of small and medium-sized enterprises, etc.

· Intelligent production: adopt high-quality automatic control software to realize production information management and improve production efficiency.

· Highly integrated automation system: The whole machine automation control system adopts a highly integrated network to make the operation more intelligent and the system performance better.

· Convenient maintenance: The equipment has a reasonable structure, simple operation, convenient maintenance and mold replacement, which greatly improves the convenience of use.

o

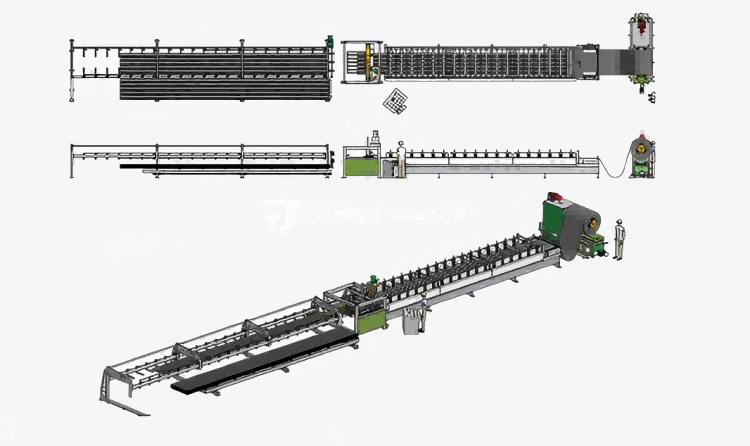

Mchine display:

O-30 corrugated sheet forming machine is mainly composed of the following core parts:

Forming machine: core equipment, responsible for the rolling and forming of materials.

PLC computer control system: fully automated intelligent control to achieve precise operation.

Shearing equipment: hydraulic shearing system to ensure precise cutting and high quality of finished products.

Hydraulic system: provides stable pressure support to improve the reliability of equipment operation.

Specifications:

1. Overall dimensions: 7500mm×1300mm×1200mm

2. Total weight: about 3500kg

3. Feed plate thickness: 0.25-0.8mm

4. Feed width: 1000mm

5. Main machine power: 4kw

6. Hydraulic shearing power: 3kw

7. Hydraulic station pressure: 10-12mpa

8. Electronic control system: The whole machine is controlled by industrial computer PLC

9. Working speed of tile press: 8000mm/min

10. Material of tile press roller: 45# steel surface hard chrome plated

11. The equipment frame is all welded by 250# I-beam

12. Middle plate thickness: 12mm

13. Transmission mode: driven by 1-inch chain and sprocket.

14. Roller: diameter 70mm

15. Number of forming rows: 17 rows

Company Profile:

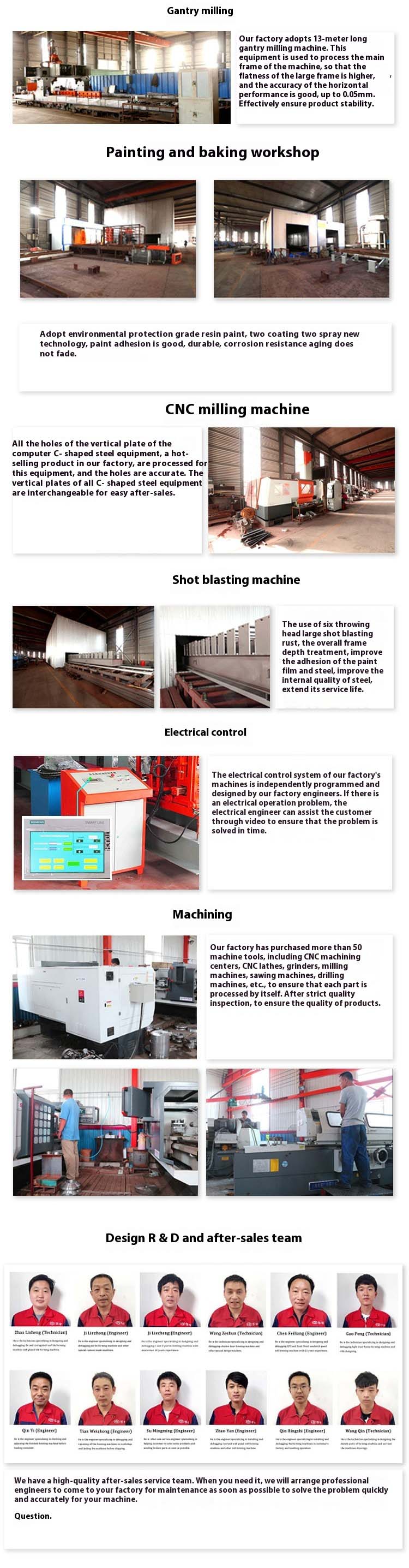

Xinnuo Roll Forming Machine Co.,LTD was founded in 1995 and has accumulated rich experience in the production of metal tile roll forming machines. More than 30 years of development have made Xinnuo the most powerful roll forming equipment supplier in North China. We now have more than 200 employees. Xinnuo's two production areas cover an area of 50,000 square meters. We have established 5 large workshops, including spare parts processing, machine welding, assembly and surface treatment factories. On the basis of traditional tile forming machines, Xinnuo has independently developed many new roll forming machine products. Including fully automatic metal plate production line, roof panel roll forming machine, wall panel roll forming machine, metal roof panel roll forming machine, C&Z purlin roll forming machine, roof panel bending machine, shearing machine, etc. With exquisite design, reasonable structure and excellent performance, Xinnuo metal tile making machine has won high praise from customers.

Exhibition:

We are often active in various high-quality exhibitions around the world!

Our R&D strength and machine quality stand the test!

Our machines are widely praised by customers!

Packing:

Our products are sold all over the world, and we have mature international packaging solutions. Through decades of cross-border logistics practice, we have continuously improved and optimized our packaging system to ensure that your goods arrive in good condition.

Quality service, win-win cooperation:

We always adhere to the service concept of "win-win + efficiency + sincerity" and attach importance to every customer's purchasing needs and equipment experience. At the same time, we will often update our machines according to customer feedback, market demand and industry trends to ensure the optimization and upgrading of the machines and not lag behind. Whether it is the early purchase or the later installation, commissioning and maintenance, we provide professional technical support and caring services to ensure that customers can use it without worries.

Looking forward to cooperating with you to create a better future!